Polystyrene (PS) Recycling

Polystyrene is an amorphous, glassy polymer that is generally rigid and relatively inexpensive. Unfilled polystyrene has a sparkle appearance and is often referred to as crystal PS or general purpose polystyrene (GPPS). High impact polystyrene grades (HIPS) are produced by adding rubber or butadiene co-polymer which increases the toughness and impact strength of the polymer. Polystyrene possess good flow properties at temperatures safely below degradation ranges, and can easily be extruded, injection molded, or compression molded. Considerable quantities of polystyrene are produced in the form of heat-expandable beads containing a suitable blowing agent which ultimately results in familiar foamed polystyrene articles.

Polystyrene (PS) has been known for well over one hundred years but its real molecular nature was not clarified until about 1920 when the work of Staudinger elucidated the materials molecular structure in the very early days of polymer science. About 1930 I.G. Farben, in Germany, first produced polystyrene, while at the same time the Dow Chemical Company commenced their ultimately successful development of the material.

Co-polymers

Pure polystyrene is brittle, but hard enough that a fairly high-performance product can be made by giving it some of the properties of a stretchier material, such as poly-butadeine rubber. The two such materials can never normally be mixed because of the amplified effect of inter-molecular forces on polymer insolubility, but if poly-butadiene is added during polymerization it can become chemically bonded to the polystyrene, forming a graft co-polymer, which helps to incorporate normal poly-butadiene into the final mix, resulting in high-impact polystyrene or HIPS, often called “high-impact plastic” in advertisements. Common applications of HIPS include toys and product casings. HIPS is usually injection molded in production. Autoclaving polystyrene can compress and harden the material.

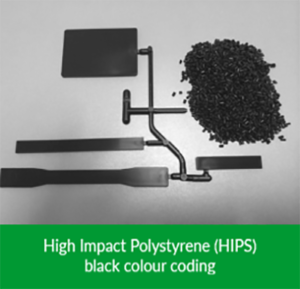

High Impact Polystyrene (HIPS) Granules in Black Color Coding

The table provided below is a typical test report ordered on presence of heavy metals and chemical contents in recycled HIPS resins in accordance with European Union’s Restrictions of Hazardous Substances (RoHS) directives. Note that for better quality recycled resins, the factory can control the manufacturing process by having relatively clean homogeneous industrial polystyrene scraps as input material and this can be specified for the production. These test results are inconsistent between replicates, thus test result is based on average result of replicate analysis.

RoHS Directive 2011/65/EU

| Test Item(s) | Unit | Method | MDL | Result No.1 | Limit |

| Cadmium (Cd) | mg/kg | Ref. IEC 62321-5:2013 and performed by ICP-AES | 2 | n.d. | 1000 |

| Lead (Pb) | mg/kg | Ref. IEC 62321-5:2013 and performed by ICP-AES | 2 | 14.2 | 1000 |

| Mercury (Hg) | mg/kg | Ref. IEC 62321-4:2013 and performed by ICP-AES | 2 | n.d. | 1000 |

| Hexavalent Chromium CR(VI) | mg/kg | Ref. IEC 62321:2008 and performed by UV-VIS | 2 | n.d. | 1000 |

| Sum of PBBs | mg/kg | – | n.d. | 1000 | |

| Monobromobiphenyl | mg/kg | Ref. IEC 62321-6:2015 and performed by GC/MS | 5 | n.d. | – |

| Dibromobiphenyl | mg/kg | 5 | n.d. | – | |

| Tribromobiphenyl | mg/kg | 5 | n.d. | – | |

| Tetrabromobiphenyl | mg/kg | 5 | n.d. | – | |

| Pentabromobiphenyl | mg/kg | 5 | n.d. | – | |

| Hexabromobiphynyl | mg/kg | 5 | n.d. | – | |

| Heptabromobiphenyl | mg/kg | 5 | n.d. | – | |

| Octabromobiphenyl | mg/kg | 5 | n.d. | – | |

| Nonabromobiphenyl | mg/kg | 5 | n.d. | – | |

| Decabromobiphenyl | mg/kg | 5 | n.d. | – | |

| Sum of PBDEs | mg/kg | – | 396 | 1000 | |

| Monobromobiphenyl ether | mg/kg | 5 | n.d. | – | |

| Dibromobiphenyl ether | mg/kg | 5 | n.d. | – | |

| Tribromobiphenyl ether | mg/kg | 5 | n.d. | – | |

| Tetrabromobiphenyl ether | mg/kg | 5 | n.d. | – | |

| Pentabromobiphenyl ether | mg/kg | 5 | n.d. | – | |

| Hexabromobiphynyl ether | mg/kg | 5 | n.d. | – | |

| Heptabromobiphenyl ether | mg/kg | 5 | n.d. | – | |

| Octabromobiphenyl ether | mg/kg | 5 | n.d. | – | |

| Nonabromobiphenyl ether | mg/kg | 5 | n.d. | – | |

| Decabromobiphenyl ether | mg/kg | 5 | n.d. | – | |

| Halogen-Chlorine (CI) (CAS No: 22537-15-1) | mg/kg | Ref. BS EN 14582:2007 Analysis performed by IC | 50 | 357 | – |

| Halogen-Bromine (Br) CAS No: 10097-32-2) | mg/kg | Ref. BS EN 14582:2007 Analysis performed by IC | 50 | 1690 | – |

| Polybrominated biphenyls (PBB)

Polybrominated diphenyl ether (PBDE) |

|